Types of Cement Used for Decorative Concrete Projects

Want your decorative concrete to look amazing but not sure which cement to use? Picking the wrong one can lead to cracks, dull finishes, or poor durability. Nobody wants to invest in a driveway, patio, or concrete slab only to see it wear down due to improper material choices.

In this guide, we’ll break down the types of cement perfect for decorative concrete projects, so your design turns out beautiful, durable, and built to last.

1. Ordinary Portland Cement

Characteristics of Ordinary Portland Cement

Ordinary Portland Cement, often just called OPC, is the most widely used type of cement worldwide. It's known for its strength and versatility, making it suitable for a broad range of construction applications, from countertops to walls. This cement is made by grinding quartz, sand, and limestone with gypsum, resulting in a fine powder that sets and hardens when mixed with water.

- Setting Time: Initial setting time is typically 30 minutes, and final setting time is about 10 hours.

- Strength: Available in different grades, with 53 grades being the strongest.

- Thermal Mass: Its high density makes it great for maintaining heat in structures.

Applications in Decorative Concrete

OPC serves as a base material in many decorative concrete applications, providing a strong foundation for creative finishes like acid staining or epoxy coatings. Popular uses include:

- Stamped Concrete: Patterns like brick, tile, or slate are imprinted for a textured finish.

- Polished Concrete: Achieves a smooth, dust-free surface that’s ideal for garage floors, warehouses, and interior spaces.

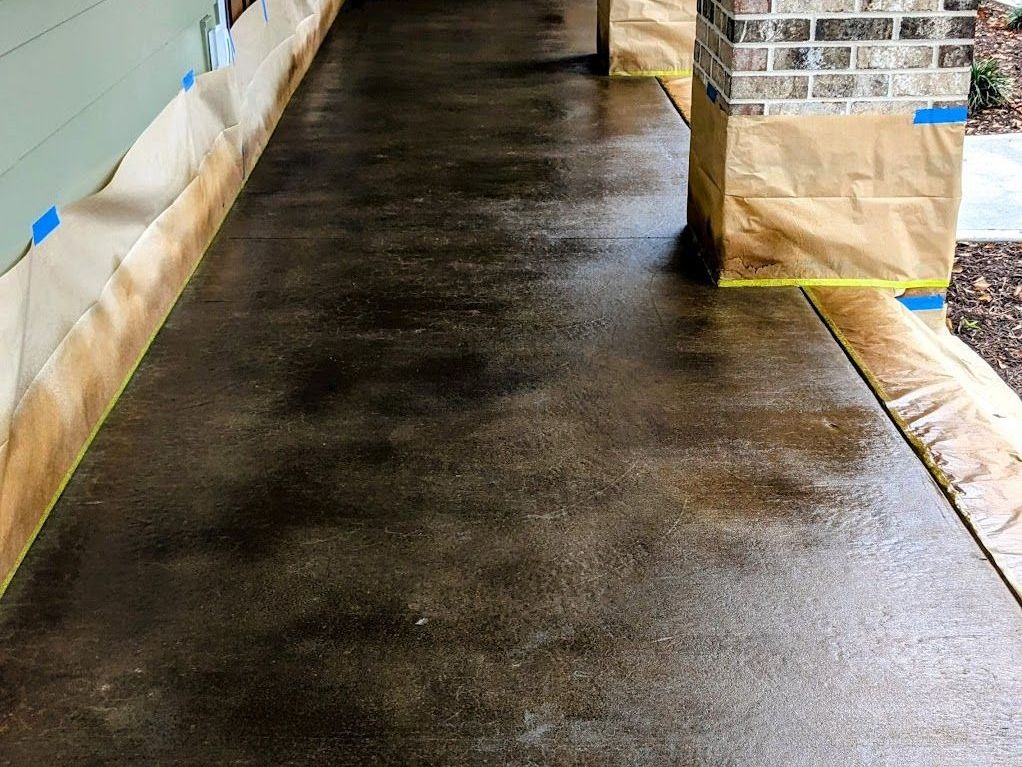

- Stained Concrete: Treated with acid stains, dyes, or pigments for vibrant color and unique aesthetics.

While OPC is not as visually distinctive as White Portland Cement, its durability makes it a favorite for structural elements paired with decorative finishes.

2. Portland Pozzolana Cement

Characteristics of Portland Pozzolana Cement

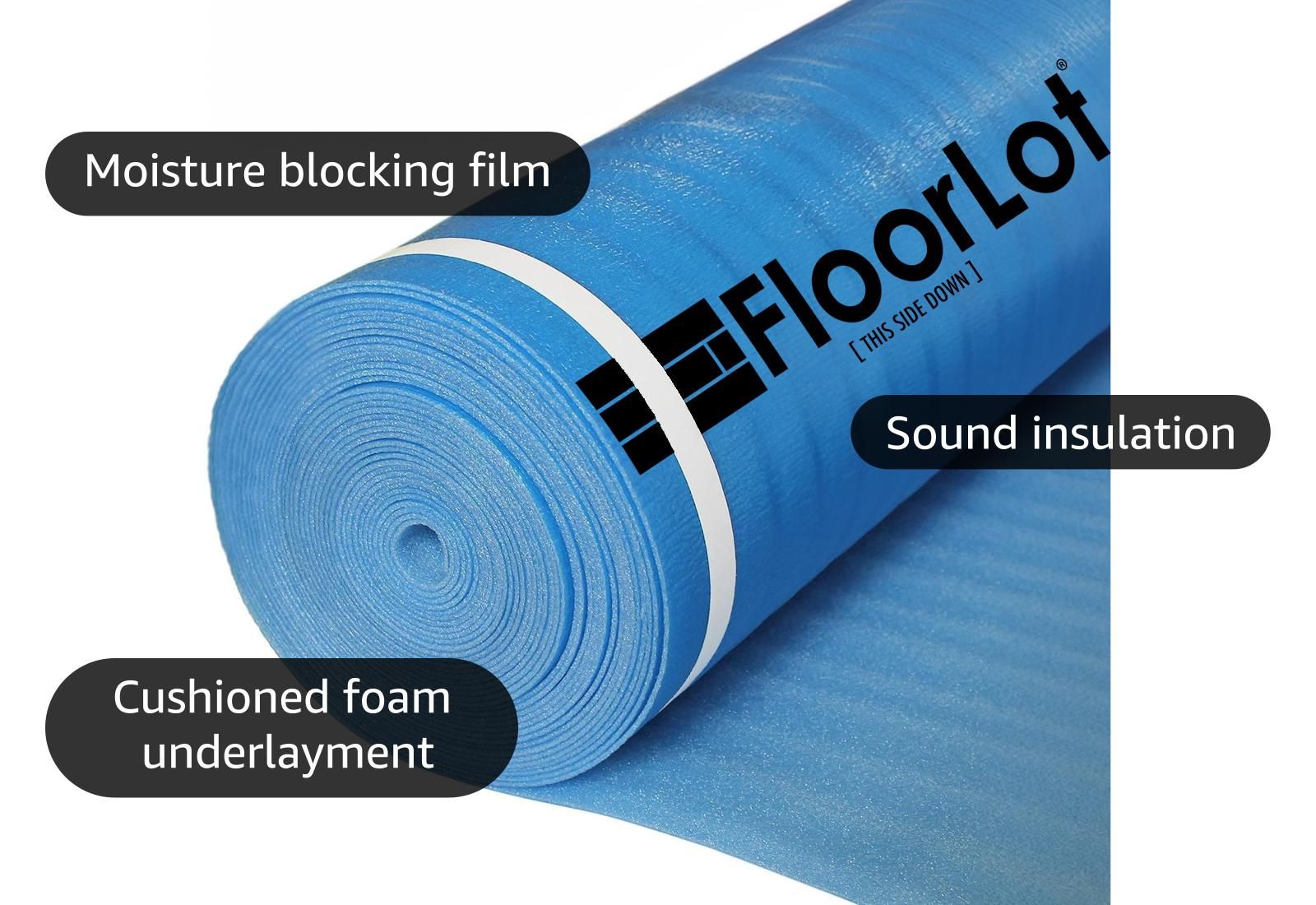

Portland Pozzolana Cement (PPC) is a blend of Portland cement and pozzolanic materials like fly ash. These additives enhance the cement's properties, improving its resistance to moisture and chemical reactions like mold and salt attacks. PPC also generates less heat, reducing the risk of cracks in large hardscape projects such as decks or porches.

Applications in Decorative Concrete

PPC is particularly suited for projects demanding environmentally friendly materials:

- Sidewalks: With reduced abrasion and improved durability, PPC is perfect for high-traffic areas.

- Basements: Its waterproofing qualities make it ideal for damp environments.

- Marine Structures: Its resistance to chlorides protects concrete slabs exposed to saltwater.

- LEED Projects: Its sustainability aligns with modern green building certifications.

3. Quick Setting Cement

Characteristics of Quick Setting Cement

Quick setting cement is crafted to reach its initial set in just minutes, making it perfect for projects like renovations or emergency repairs. This cement achieves rapid results through accelerated hydration, often requiring tools like an angle grinder and trowel for precision work.

Applications in Decorative Concrete

Quick setting cement is ideal for projects demanding fast turnaround:

- Garage Floors: Reduces downtime during repairs or overlays with epoxy coatings.

- Stamped Concrete: Ensures patterns retain their details even in high-heat or underwater applications.

- Kitchen Countertops: Allows for quick curing and minimal dust in confined interior spaces.

4. Colored Cement

Characteristics of Colored Cement

Colored cement, or pigmented cement, combines hydraulic cement with synthetic or natural pigments to achieve vibrant aesthetics. Adding acrylic paint, polymer, or even resin to the mix further enhances its customization potential.

Applications in Decorative Concrete

Colored cement unlocks limitless possibilities for creative designs:

- Pavers: Custom colors for pathways and porches that match the surrounding hardscape.

- Concrete Countertops: Vibrant hues create stunning focal points for kitchens and bathrooms.

- Patios: Adds a touch of beauty to outdoor spaces while resisting ultraviolet damage.

5. High Alumina Cement

Characteristics of High Alumina Cement

High alumina cement is prized for its strength and ability to withstand extreme heat and chemical reactions. Made by blending calcined bauxite with lime, it offers unmatched resistance to abrasion and water exposure.

Applications in Decorative Concrete

- Fireplaces: Withstands high temperatures without compromising durability.

- Precast Concrete Designs: Ideal for intricate molds requiring strength and abrasion resistance.

- Decorative Concrete Sealer: Enhances the beauty of finishes in harsh environments.

Wrapping It Up

Choosing the right cement is crucial to achieving the desired aesthetics, durability, and waterproofing for your patio, driveway, or interior floors. From stamped concrete to stained countertops, each cement type offers unique benefits tailored to specific design needs and budget constraints. Want help with your project? Contact Zachary Daniel Concrete in Greenville, SC for expert advice and a free quote.

FAQs

What is decorative concrete?

Decorative concrete is designed for visual appeal, combining functionality with aesthetics. It can include stamped concrete, polished floors, or stained countertops for unique finishes.

Can colored cement be used outdoors?

Yes, it’s great for porches, pavers, and other outdoor hardscape applications. Pair it with a concrete sealer for added protection.

What tools are required for quick setting cement?

You'll need a trowel, vacuum, primer, and potentially an angle grinder for detailed work.